SMT Defect List

SMT Defect List and SMT Troubleshooting (SMT / SMD Problem and Solution)

SMT (Surface Mount Technology), like other SMD Soldering and PCB assembly technology is not ZERO-Defect soldering process. There will always be some or the other defect in any Electronics PCB assembly in both Thru-Hole and SMT.

Here I will discuss some of the most common faults and causes of SMT defects and possible solution and troubleshooting.

Common Faults in SMT:

-

Solder balls

-

Solder beading

-

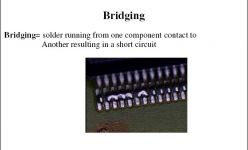

Bridging

-

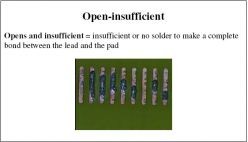

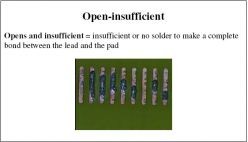

Open- Insufficient

-

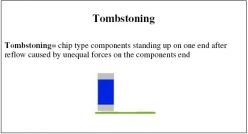

Tombstoning

-

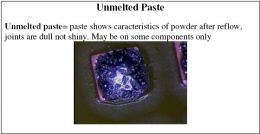

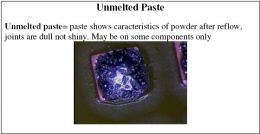

Unmelted paste

-

Excessive filet

-

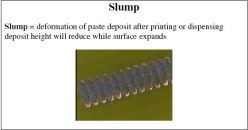

Slump

-

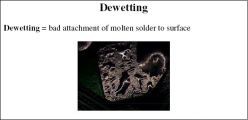

Dewetting

-

Disturb joint

-

Orange Skinning

Solder Balls – Possible cause:

-

Solder Paste smearing on underside of stencil.

-

What is squeegee pressure?

-

Is stencil underside cleaned with a solvent and is solvent still present after cleaning?

-

Is stencil proper aligned with PCB?

Solution to Solder Ball Problems:

-

Check squeegee pressure

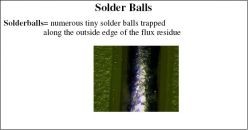

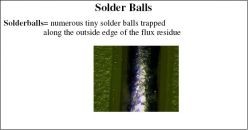

Solder balls = numerous tiny solder balls trapped along the outside edge of the flux residue

-

Check for proper gasketting and alignment

-

Check if cleaning solvent is completely evaporated before printing

Oxidised paste – Possible cause

-

Was paste shipped refrigerated?

-

Did paste spend a long time in a hot area?

-

Was old paste returned to jar?

Solder balls = numerous tiny solder balls trapped along the outside edge of the flux residue

-

Was jar put back into refrigeration after opening?

-

Is alloy sensitive to oxidation?

Solution to Oxidised Solder Paste Problems:

-

Run fresh paste from a different lot under same conditions and see if solder bars go away.

Oxidised paste – Possible cause

-

Squeegee pressure too high

-

Paste gets squeezed out between stencil and board

Solution: Reduce squeegee pressure

Possible cause:

-

Drying out of paste after printing

-

What is specified tack time of paste?

Solution: Run a PCB with fresh paste and see if problem goes away

Possible cause:

-

Too slow ramp up in reflow profile

Solution: Run recommended profile and see if problem stays

Possible cause:

-

Too rapid ramp up in flow profile

Solution: Run a slower ramp up profile to give volatiles to evaporate

SOLDER BEADS – Possible cause:

-

Reflow profile ramp up slow

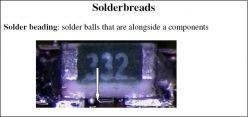

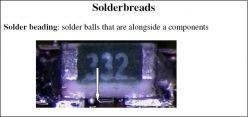

Solder beading : solder balls that are alongside a components

-

Capillary action draws unreflowed paste away from pad to somewhere under the component, it reflows there and form a bead of solder which comes out from under the component side.

Solution: Run a more rapid ramp up profile of 1.5 Degree Celsius to 2.5 Degree Celsius per second.

Possible cause:

-

Excessive amount of solder paste on component pads

-

What is stencil thickness?

-

Are apertures reduced?

-

Dispense time for a dot?

Solution:

-

Reduce aperture size of stencil or use thinner stencil

-

Use smaller needle and/or reduce purge time on dispenser

Possible cause: Paste smearing on underside of stencil

-

What is squeegee pressure?

-

Is stencil underside cleaned with a solvent and is solvent still present after cleaning?

-

Is stencil properly aligned with PCB?

Solution:

-

Check squeegee pressure

-

Check for proper gasketting and alignment

-

Check if cleaning solvent is completely evaporated before printing

BRIDGING – Possible Cause:

-

Cold slumping

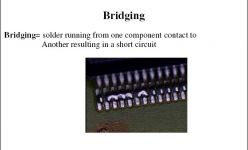

Bridging = solder running from one component contact to another resulting in a short circuit

-

Is paste flowing apart after printing, height of deposit reduces and surface increases.

Solution:

-

Check viscosity of paste, too low viscosity may result in cold slumping

-

Check print speed, too rapid print speed may result in shearing of paste and degrading its thickness

-

Check temperature in printer, too high temperature brings viscosity down

Bridging = solder running from one component contact to another resulting in a short circuit

Possible Cause:

-

Hot slumping

-

Is paste flowing apart during ramp up part of reflow profile

Solution: Shorten duration of ramp up cycle in reflow profile

Possible Cause:

-

Paste smearing on underside of stencil

-

Paste can be outside pad area and form solder balls between two component leads resulting in a bridge

Solution – Reduce squeegee and check pcb-stencil alignment and gasketting

Possible Cause:

-

Excessive solder paste being deposited on the pads

-

While placing a component on the pads the paste is smeared out and may form a bridge to an adjacent pad

Remedy:

-

Reduce amount of solder paste

-

Increasing print speed may

-

Reduce stencil thickness

Open-insufficient – Possible cause:

Opens and insufficient = insufficient or no solder to make a complete bond between the lead and the pad

-

Scooping during printing

-

Excessive squeegee pressure on a polypropylene squeegee may cause scooping

Remedy: Reduce squeegee pressure or use a harder durometer type of squeegee or use a metal squeegee

Possible Cause: Blocking of stencil aperture with dried up paste

Remedy: Unblock apertures and clean stencil

Possible Cause:

Opens and insufficient = insufficient or no solder to make a complete bond between the lead and the pad

-

Foreign material on solder pad

-

Was solder mask printed on pad?

Remedy: Use another PCB

Possible Cause:

-

Too high squeegee speed

-

Paste cannot get into the apertures

Remedy: Reduce squeegee speed

Possible cause: Solder paste viscosity and/or metal content too low

Remedy: Check viscosity and metal content

TOMBSTONING

Tombstoning = chip type components standing up on one end after reflow caused by unequal forces on the components end

Possible cause: Unequal placement of components on pads prior to Reflow results in unbalanced solder forces.

Remedy: Check if placement equipment places properly.

Possible cause: Unequal heat sink i.e. ground planes inside PCB layers may draw heat away from pad.

Remedy: Increase soak time (plateau) or reflow profile so that all components are on.

UNMELTED PASTE – Possible cause:

-

To cold reflow profile

-

Solder paste cannot melt completely

Unmelted paste = paste shows characteristics of powder after reflow, joints are dull not shiny. May be on some components only

Remedy: Check reflow profile, make sure peak temperature and time above liquids (183C) are high enough and soak (plateau) is long enough.

Unmelted paste = paste shows characteristics of powder after reflow, joints are dull not shiny. May be on some components only

Excessive Fillet

Possible cause: Too much solder paste deposited on pads

Remedy:

-

If excess solder occurs on all components reduce overall stencil thickness or reduce dispenser purge time

-

If excess solder occurs on some places only reduce stencil thickness or dispense purge time for these components only

Excessive fillet = bulbous appearance of joint where outlines of the leads are obscured by the quantity of solder on them

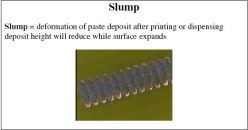

Slump Cold Slump – Possible cause:

Viscosity of paste to low or metal content to low

Slump = deformation of paste deposit after printing or dispensing deposit height will reduce while surface expands

Remedy: Use different type of paste with higher viscosity or higher metal content

Possible cause: Paste came in contact with a cleaning solvent or other alien product

Remedy:

-

Make sure there are no solvents presents after cleaning the screen

-

Never try to revive the paste by adding some compound

Possible cause:

Slump = deformation of paste deposit after printing or dispensing deposit height will reduce while surface expands

-

Squeegee pressure to high

-

Paste is shearing due to excessive pressure applied to it thickeners in paste are destroyed

Remedy: Use new paste and reduce squeegee pressure

Possible cause: Temperature of paste is too high while printing or dispensing

Remedy:

-

Check temperature inside printer

-

Reduce pressure on squeegee

-

Reduce on pressure on syringe when dispensing

Hot Slump

Possible cause: Too slow ramp up in reflow profile

Remedy: Increase ramp up temperature, make sure to have a ramp up between 2 Degree Celsius to 3 Degree Celsius per second

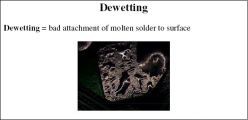

DEWETTING – Possible cause:

Dewetting = bad attachment of molten solder to surface

-

Unwanted material on surface which prevents solder from attaching to surface, i.e. solder mask, fingerprints or oxides.

Remedy:

-

Clean boards first

-

Use different batch of boards

Possible cause:

Dewetting = bad attachment of molten solder to surface

-

Bad alloy in HAL process, i.e. too much Cu elevates melting point of HAL alloy

remedy:

-

Increase peak temperature in reflow

-

Use different batch of boards

Disturbed Joint Possible cause:

A source of vibration that is transmitted through the pcb during the liquids state of the reflow profile

Remedy:

-

Find and fix source of vibration

-

Adjust reflow

Disturbed Joint = dull, rough appearance of solder in an alloy that is normally bright and shiny

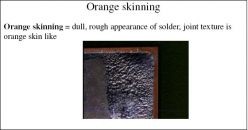

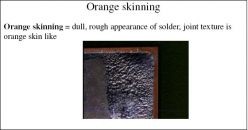

Orange skinning – Possible cause:

Orange skinning = dull, rough appearance of solder, joint texture is orange skin like

-

Too high in peak zone

-

Residue is burned or rosin was cooking

Remedy:

-

Lower peak zone temperature

Possible cause:

-

Too long exposure to temperatures between activation temp and reflow = (depending on alloy)

Remedy:

Orange skinning = dull, rough appearance of solder, joint texture is orange skin like

-

Shorten time in soak or lower soak temperatures

Possible cause:

-

Preheating too high

Remedy:

-

Lower preheat temperatures

Use Nowadays SMT Equipment can reduce the SMT Defect to a very low level:

Automatic SMT Production Line:

PCB Loader➡SMT Stencil Printer➡PCB Conveyor➡SPI➡Pick and Place Machine➡AOI➡SMT Reflow Oven➡AOI➡PCB Unloader➡DIP Component Insert Line➡Wave Soldering Machine➡THT PCB unloader

Keywords:

SMT Assembly line, PCB Assembly line, LED Production line, Automatic SMT Assembly line,Semi Automatic SMT Assembly line, JUKI Assembly Line, Samsung Assembly Line, HanwhaAssembly Line, Panasonic Assembly Line, Siemens Assembly Line, FUJI Assembly Line,Yamaha Assembly Line.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including

SMT Reflow Oven,

Wave Soldering Machine,

Pick and Place Machine,

SMT Stencil Printer,

SMT AOI SPI Machine,

SMT Reflow Oven,

SMT Peripheral Equipment,

SMT Assembly line,

SMT Spare Parts

etc any kind SMT machines you may need, please contact us for more information:

wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: sales@flason-smt.com |

|

|

|

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service ! |

|